Views: 8 Author: Site Editor Publish Time: 2022-01-27 Origin: Site

How to classify heat exchangers?

According to the heat transfer method, it can be divided into: partition wall heat exchanger, regenerative heat echanger, fluid connection indirect heat exchanger, direct contact heat exchanger, and double heat exchanger.

According to the purpose, it can be divided into: heater, preheater, superheater, evaporator.

According to the structure, it can be divided into: floating head heat exchanger, fixed tube sheet heat exchanger, U-shaped tube sheet heat exchanger, plate heat exchanger, etc.

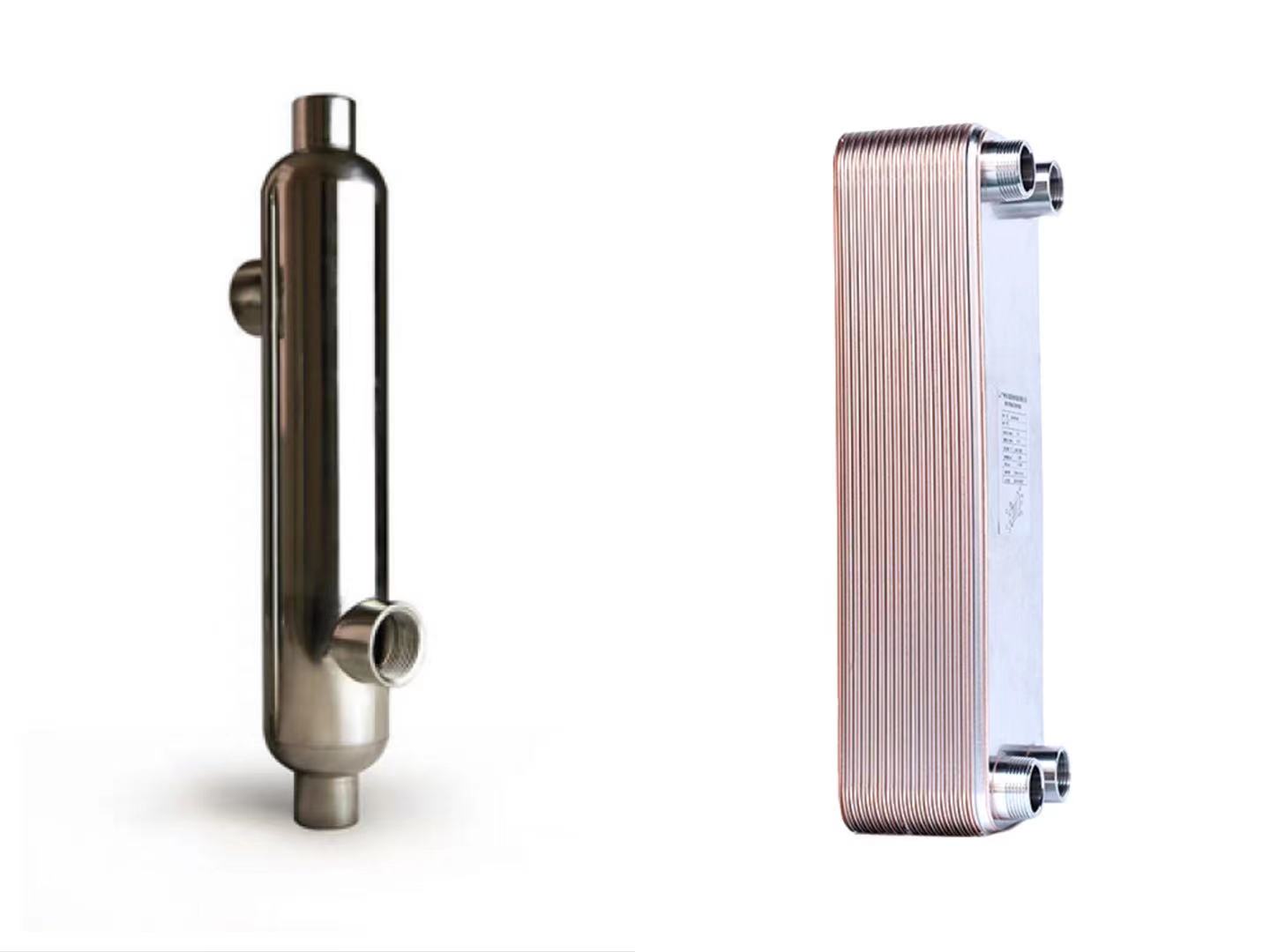

One of the differences between shell and tube heat exchanger and plate heat exchanger:

1. Shell and tube heat exchanger structure:

The shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube sheet, baffle plate (baffle) and tube box. The shell is mostly cylindrical with a tube bundle inside, and both ends of the tube bundle are fixed on the tube plate. There are two kinds of hot fluid and cold fluid for heat transfer, one is the fluid inside the tube, called the tube side fluid; the other is the fluid outside the tube, called the shell side fluid.

2. Structure of plate heat exchanger:

The detachable plate heat exchanger is made up of many stamped corrugated thin plates at a certain interval, sealed with gaskets around them, and overlapped with frames and compression screws. The four corner holes of the plate and gasket constitute the fluid distributor and the liquid collecting pipe. At the same time, the cold fluid and the hot fluid are reasonably separated so that they are separated on both sides of each plate. Flow in the channel and exchange heat through the plate.

One of the differences between shell and tube heat exchangers and plate heat exchangers:

1. Features of shell and tube heat exchanger:

(1) High efficiency and energy saving, the heat transfer coefficient of the heat exchanger is 6000-8000W/(m2·k).

(2) All stainless steel production, long service life, up to 20 years.

(3) Changing laminar flow to turbulent flow improves heat transfer efficiency and reduces thermal resistance.

(4) Fast heat transfer, high temperature resistance (400 degrees Celsius), high pressure resistance (2.5 MPa).

(5) Compact structure, small floor space, light weight, convenient installation, saving civil construction investment.

(6) Flexible design, complete specifications, strong practicability and saving money.

(7) It has a wide range of application conditions and is suitable for pressure, temperature range and heat exchange of various media.

(8) Low maintenance cost, simple operation, long cleaning cycle and convenient cleaning.

(9) The use of nano thermal film technology can significantly improve the heat transfer coefficient.

(10) Widely used in thermal power, industrial and mining, petrochemical, urban central heating, food and medicine, energy electronics, machinery and light industry.

(11) The copper tube with fins rolled on the outer surface of the heat transfer tube has high thermal conductivity and large heat transfer area.

(12) The guide plate guides the shell side fluid to flow continuously in the disconnection in the heat exchanger. The distance between the guide plates can be adjusted according to the optimal flow. The structure is sturdy, which can meet the heat transfer of the shell side fluid with large flow or even super flow and high pulsation frequency.

(13) When the shell side fluid is oil, it is suitable for low viscosity, clean heat transfer oil.

2. Features of plate heat exchanger:

(1) High heat transfer coefficient

(2) The logarithmic average tempera

(3) Small footprint

(4) Easy to change the heat exchange area or process combination

(5) Light weight

(6) Low price

(7) Easy to make

(8) Easy to clean

(9) Small heat loss

【Conclusion】

In solar water heating systems, we recommend plate heat exchangers for general domestic water heating systems, while we recommend tube heat exchangers for large systems and swimming pool systems.