Views: 15 Author: Site Editor Publish Time: 2020-09-25 Origin: Site

【Abstract】

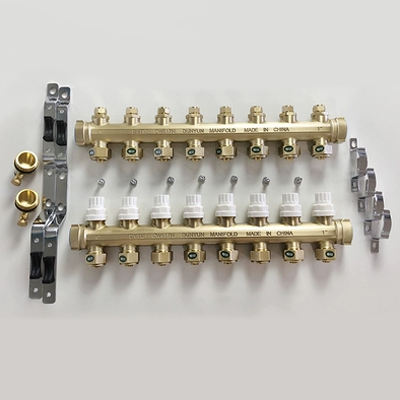

Floor heating water separator is a diversion device that divides the hot water or hot steam sent from the main heating pipe into several sub-pipes to each room. It is an indispensable equipment for floor radiant heating. To a certain extent, floor heating The water heater determines the service life of the floor heating. In order to achieve a good floor heating system circulation, the correct use of floor heating water separators is very important to the entire floor radiant heating system.

At present, the water separators used in the floor heating system mainly include two types of metal floor heating water separators and plastic water separators. Metal water separators are divided into two varieties: copper and stainless steel; plastic water separators are divided into polypropylene, polybutene, glass fiber reinforced nylon and other varieties. The current market is still dominated by metal water separators. With the promotion of some domestic manufacturers and the entry of European and Korean products, the number of engineering applications is growing rapidly.

【Text】

Floor heating water separator function

1. Adjust the temperature

The floor heating water separator is used for diversion. If the water flow rate is large and the circulation is fast, the indoor temperature will be high; if each valve is half-open, or a single half-open, the amount of hot water in the pipeline will decrease and the water circulation will slow down. The corresponding indoor temperature is low; if the hot water is completely turned off and the hot water does not circulate, it means that there is no heating in the room. Therefore, it is said that the indoor temperature can be adjusted by making good use of the floor heating water separator.

Tips: If you want to accurately control the temperature in different rooms, it is best to install a special floor heating thermostat.

2. Separate heating

When designing and installing the floor heating system for large units, outlet pipes will be installed in different areas

Operation and maintenance of water separator

1. Run hot water for the first time

In the first operation, hot water should be gradually injected and the geothermal heating should be started for the first time. When the hot water is supplied, first open the manifold water supply loop valve to gradually increase the temperature of the hot water and inject it into the pipeline to circulate. Check whether there is any abnormality in the manifold interface, and gradually open the branch valves of the manifold. If there is leakage in the water separator and pipeline, close the main water supply valve in time and contact the developer or geothermal company in time.

2. First run exhaust method

During the first operation of floor heating, air locks are likely to occur due to the pressure and water resistance in the pipeline, causing the supply and return water to not circulate and the temperature to be unequal, so it should be exhausted one by one. The method is: close the total return valve of heating and each loop adjustment, first open a regulating valve on the water separator, then open the exhaust valve on the water separator backwater bar to discharge water and exhaust, and then close the air after draining. This valve opens the next valve at the same time. By analogy, after each air is drained, the valve is opened, and the system is officially running.

3. Clean the filter if the outlet pipe is not hot

A filter is installed before each water separator. When there are too many magazines in the water, the filter should be cleaned in time. When there are too many magazines in the filter, the water outlet pipe will not be hot, the floor heating will not be hot, etc., and the filter should usually be cleaned once a year.

4. Release all the water after heating

After the geothermal heating period ends each year, all the filtered pipe water in the geothermal network should be discharged. Because the boiler pipe water contains a lot of tiny particles such as slime, impurities, rust and slag, the water quality is turbid, and the inner diameter of the geothermal pipe network is very small, and the precipitation of calcium, magnesium, salt and other substances contained in the water will generate hard scale and coat the geothermal heat. On the inner wall of the pipe network, the bends are more serious and cannot be washed away even by pressurized water flow. This is also the reason for the floor heating to be cleaned.

Tips for using floor heating water separator

1. The water separator can control the heating temperature of each room or area by way, and the user can adjust the temperature of the room according to their own needs; the manual exhaust valve of the water separator allows the user to discharge the gas in the pipeline by themselves to ensure that each The heating temperature of the pipeline.

2. There is a filter on the front end of the water separator, and the user regularly or irregularly removes the filter at the bottom of the filter, cleans it, and installs it during the annual heating period to ensure the cleanliness of the water pipe. After heating, the pipe network should be flushed with clean water.

3. At the beginning of heating, the internal temperature will not be felt immediately. During this period, the indoor ground concrete layer is gradually being heated to store thermal energy. After 2-4 days, it can reach the design temperature. For example, the user's own heating water temperature should not exceed 65℃.

4. If you are not at home for a long time, the main valve of the water separator can be used to reduce the circulating water volume and never close it all. If the room is not heated throughout the winter, the water in the pipe should be blown out.

【Conclusion】

As the heart of the underfloor heating system, only by mastering a certain method of using the underfloor heating manifold, can the service life of the underfloor heating be extended and the use effect of the underfloor heating can be maximized.