Views: 10 Author: Site Editor Publish Time: 2021-01-08 Origin: Site

【Abstract】

The heat exchanger is a device that transfers part of the heat of the hot fluid to the cold fluid, also known as the heat exchanger. Heat exchangers are general equipment in chemical, petroleum, power, food and many other industrial sectors, and they occupy an important position in production.

【Text】

How to classify heat exchangers?

According to the heat transfer method, it can be divided into: partition wall heat exchanger, regenerative heat exchanger, fluid connection indirect heat exchanger, direct contact heat exchanger, and double heat exchanger.

According to the purpose, it can be divided into: heater, preheater, superheater, evaporator.

According to the structure, it can be divided into: floating head heat exchanger, fixed tube sheet heat exchanger, U-shaped tube sheet heat exchanger, plate heat exchanger, etc.

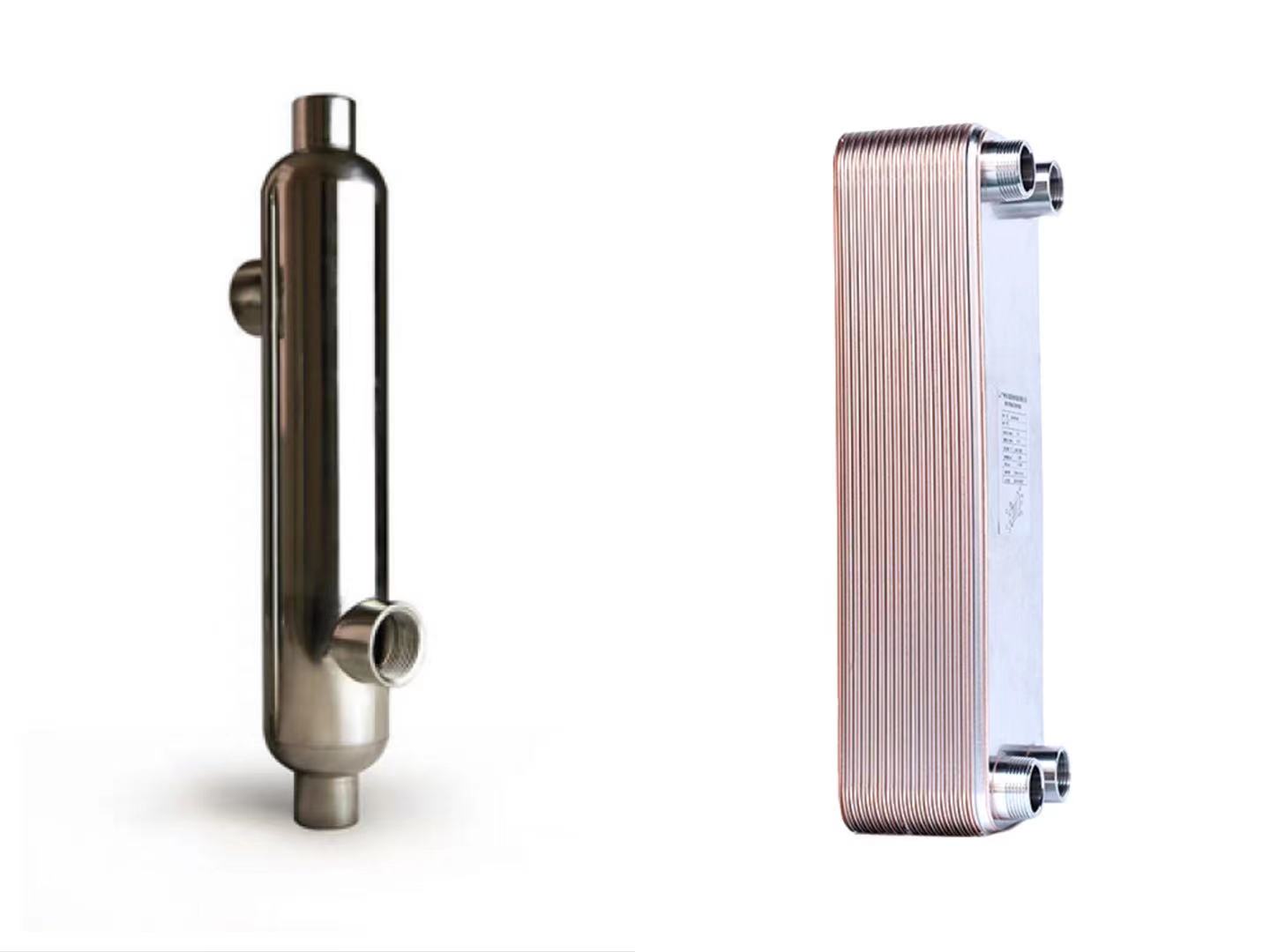

One of the differences between shell and tube heat exchanger and plate heat exchanger: structure

1. Shell and tube heat exchanger structure:

The shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube sheet, baffle plate (baffle) and tube box. The shell is mostly cylindrical with a tube bundle inside, and both ends of the tube bundle are fixed on the tube plate. There are two kinds of hot fluid and cold fluid for heat transfer, one is the fluid inside the tube, called the tube side fluid; the other is the fluid outside the tube, called the shell side fluid.

In order to improve the heat transfer coefficient of the fluid outside the tube, a number of baffles are usually arranged in the tube shell. The baffle can increase the velocity of the fluid in the shell side, make the fluid pass through the tube bundle multiple times at a specified distance, and improve the turbulence of the fluid.

The heat exchange tubes can be arranged in equilateral triangle or square on the tube plate. The equilateral triangle is arranged compactly, the fluid outside the tube has a high degree of turbulence, and the heat transfer coefficient is large. The square arrangement is convenient for cleaning the outside of the pipe and is suitable for fluids that are prone to fouling.

2. Structure of plate heat exchanger:

The detachable plate heat exchanger is made up of many stamped corrugated thin plates at a certain interval, sealed with gaskets around them, and overlapped with frames and compression screws. The four corner holes of the plate and gasket constitute the fluid distributor and the liquid collecting pipe. At the same time, the cold fluid and the hot fluid are reasonably separated so that they are separated on both sides of each plate. Flow in the channel and exchange heat through the plate.

One of the differences between shell and tube heat exchangers and plate heat exchangers: Features

1. Features of shell and tube heat exchanger:

(1) High efficiency and energy saving, the heat transfer coefficient of the heat exchanger is 6000-8000W/(m2·k).

(2) All stainless steel production, long service life, up to 20 years.

(3) Changing laminar flow to turbulent flow improves heat transfer efficiency and reduces thermal resistance.

(4) Fast heat transfer, high temperature resistance (400 degrees Celsius), high pressure resistance (2.5 MPa).

(5) Compact structure, small floor space, light weight, convenient installation, saving civil construction investment.

(6) Flexible design, complete specifications, strong practicability and saving money.

(7) It has a wide range of application conditions and is suitable for pressure, temperature range and heat exchange of various media.

(8) Low maintenance cost, simple operation, long cleaning cycle and convenient cleaning.

(9) The use of nano thermal film technology can significantly improve the heat transfer coefficient.

(10) Widely used in thermal power, industrial and mining, petrochemical, urban central heating, food and medicine, energy electronics, machinery and light industry.

(11) The copper tube with fins rolled on the outer surface of the heat transfer tube has high thermal conductivity and large heat transfer area.

(12) The guide plate guides the shell side fluid to flow continuously in the disconnection in the heat exchanger. The distance between the guide plates can be adjusted according to the optimal flow. The structure is sturdy, which can meet the heat transfer of the shell side fluid with large flow or even super flow and high pulsation frequency.

(13) When the shell side fluid is oil, it is suitable for low viscosity, clean heat transfer oil.

2. Features of plate heat exchanger:

(1) High heat transfer coefficient

Since the different corrugated plates are reversed, a complicated channel is formed, so that the fluid between the corrugated plates flows in a three-dimensional rotating flow. Turbulent flow can be generated at a low Reynolds number (generally Re=50-200), so heat transfer The coefficient is relatively high, generally considering that the red color is 3-5 times that of the shell-and-tube type.

(2) The logarithmic average temperature difference is large, and the terminal temperature difference is small

In the shell-and-tube heat exchanger, there are two fluid flows in the tube side and the tube side respectively. Generally speaking, they are cross-flow, and the log-average temperature difference correction coefficient is very small. Most plate heat exchangers flow in parallel or countercurrent, and the correction factor is generally around 0.95. In addition, the flow of hot and cold fluid in the plate heat exchanger is parallel to the flow of hot and cold fluid in the heat exchanger.

The hot surface and no bypass make the temperature difference at the end of the plate heat exchanger small, and the heat transfer to water can be less than 1℃, while the shell-and-tube heat exchanger is generally 5℃.

(3) Small footprint

The plate heat exchanger has a compact structure, and the heat transfer area per unit volume is 2-5 times that of the shell-and-tube heat exchanger. Unlike the shell-and-tube heat exchanger, it does not need to reserve a maintenance position for the extraction of the tube bundle. Therefore, in order to achieve the same heat transfer capacity, the area of the plate heat exchanger is about 1/5-1/8 of the shell-and-tube heat exchanger.

(4) Easy to change the heat exchange area or process combination

As long as you increase or decrease a few plates, you can increase or decrease the heat transfer area. By changing the plate layout or replacing multiple plate types, the required process combination can be realized, and the heat exchange area of the shell-and-tube heat exchanger can be adapted to the new heat exchange conditions. It is almost impossible to increase the heat exchange area of a shell and tube heat exchanger.

(5) Light weight

The plate thickness of the plate heat exchanger is only 0.4-0.8 mm, and the tube thickness of the shell and tube heat exchanger is 2.0-2.5 mm. The shell and tube heat exchanger is much heavier than the plate heat exchanger frame. The plate heat exchanger generally only accounts for about 1/5 of the weight of the tube and shell.

(6) Low price

The plate heat exchanger has the same material, the same heat exchange area, and the price is 40% to 60% lower than that of the shell and tube heat exchanger.

(7) Easy to make

The heat transfer plate of the plate heat exchanger is stamped and processed, which has a high degree of standardization and can be mass-produced. Shell and tube heat exchangers are usually manufactured by hand.

(8) Easy to clean

As long as the frame plate heat exchanger loosens the pressure bolts, the plate heat exchanger tube bundle can be loosened, and the plate heat exchanger can be removed for mechanical cleaning. This is very convenient for the heat exchange process of equipment that needs to be cleaned frequently.

(9) Small heat loss

In the plate heat exchanger, only the shell plate of the heat exchange plate is exposed to the atmosphere, and the heat loss is negligible, and no insulation measures are required.

【Conclusion】

In solar water heating systems, we recommend plate heat exchangers for general domestic water heating systems, while we recommend tube heat exchangers for large systems and swimming pool systems.